SYSTEM INTEGRATORS

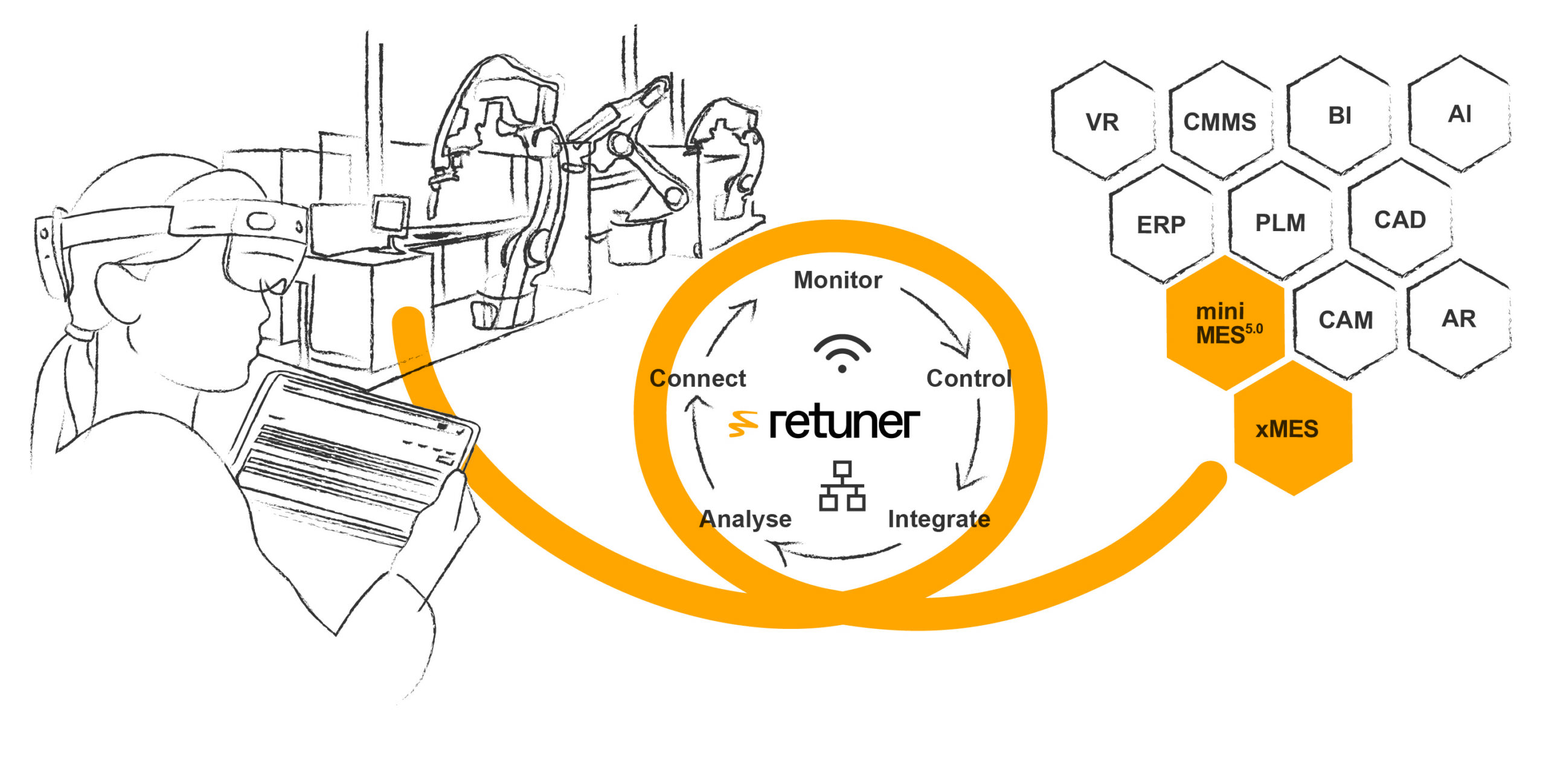

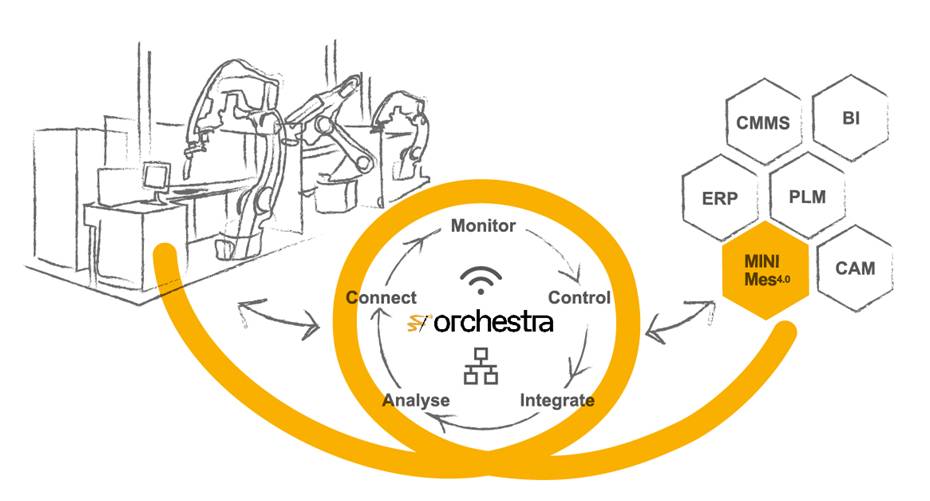

RETUNER is the 360-degree solution for digitalising machines and plants, allowing manufacturing SMEs to adopt the rules of Industry 4.0 and set up continual improvements in production.

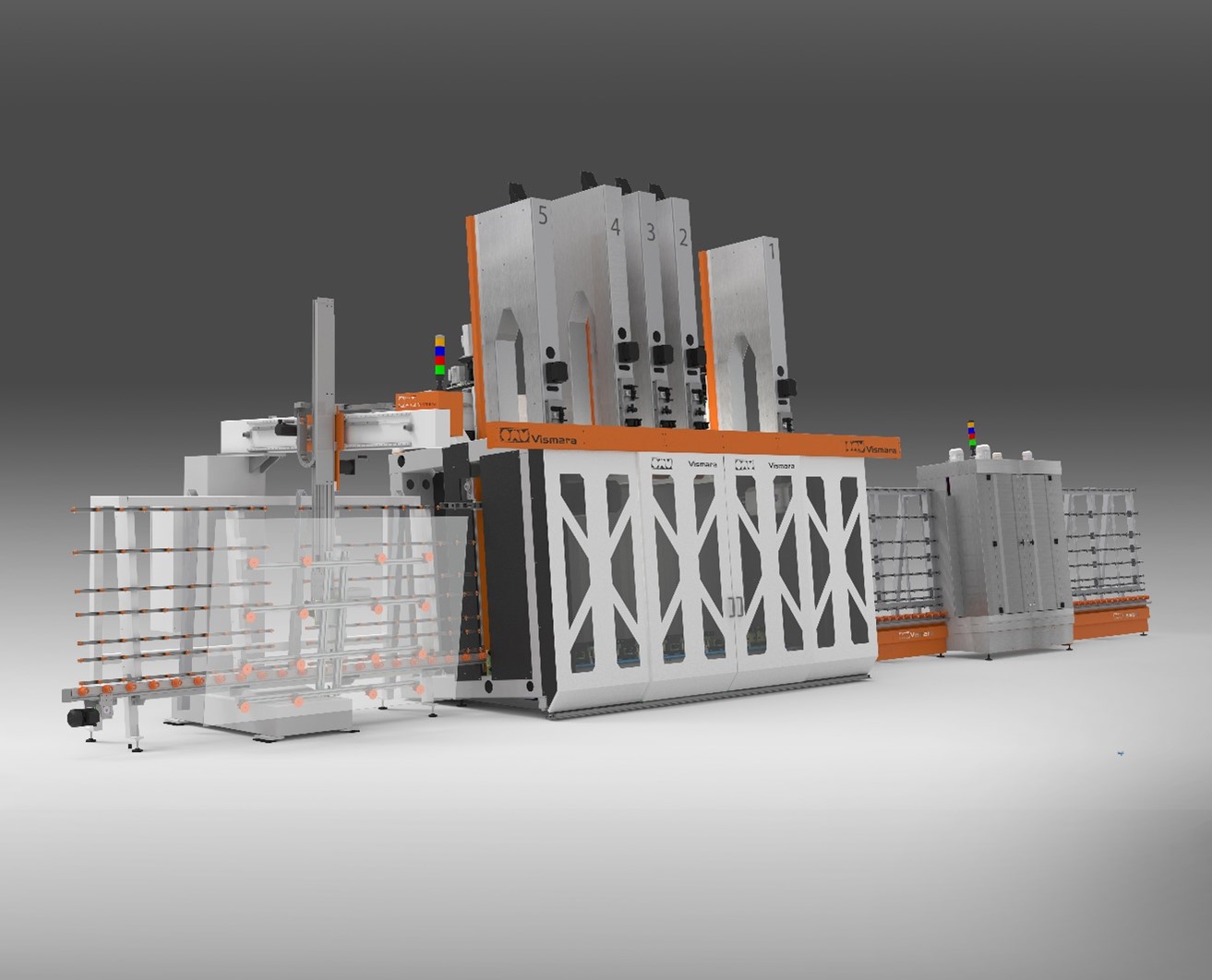

System integrators can take advantage of our in-depth knowledge of machinery by the major brands to help carry out projects to digitalise the production processes of their customers.

RETUNER can be used with third party interfaces and offers standard interfaces in order to integrate with existing ICT systems used in the customer’s company.

Thanks to RETUNER system integrators can easily link their products and offer the possibility to integrate their own technical and management systems with the production processes of the manufacturing customer.

- Offer solutions based on RETUNER technology to your customers, such as

- Industry 4.0 ready, digitised machines, based on standard interconnections with the customers ICT systems.

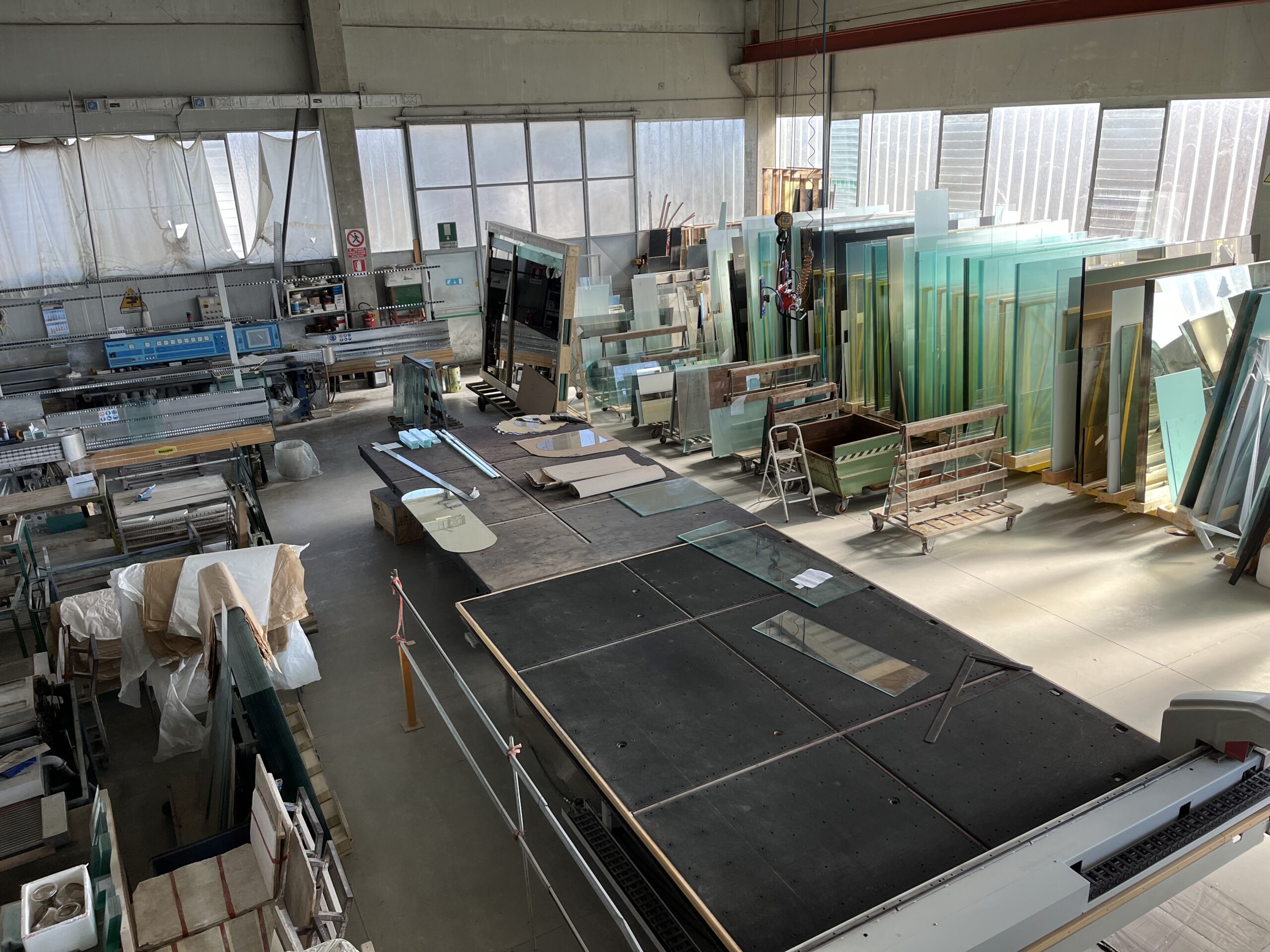

- A digital solution that allows the interconnection of multi-brand machinery creating a complete Industry 4.0 shopfloor.

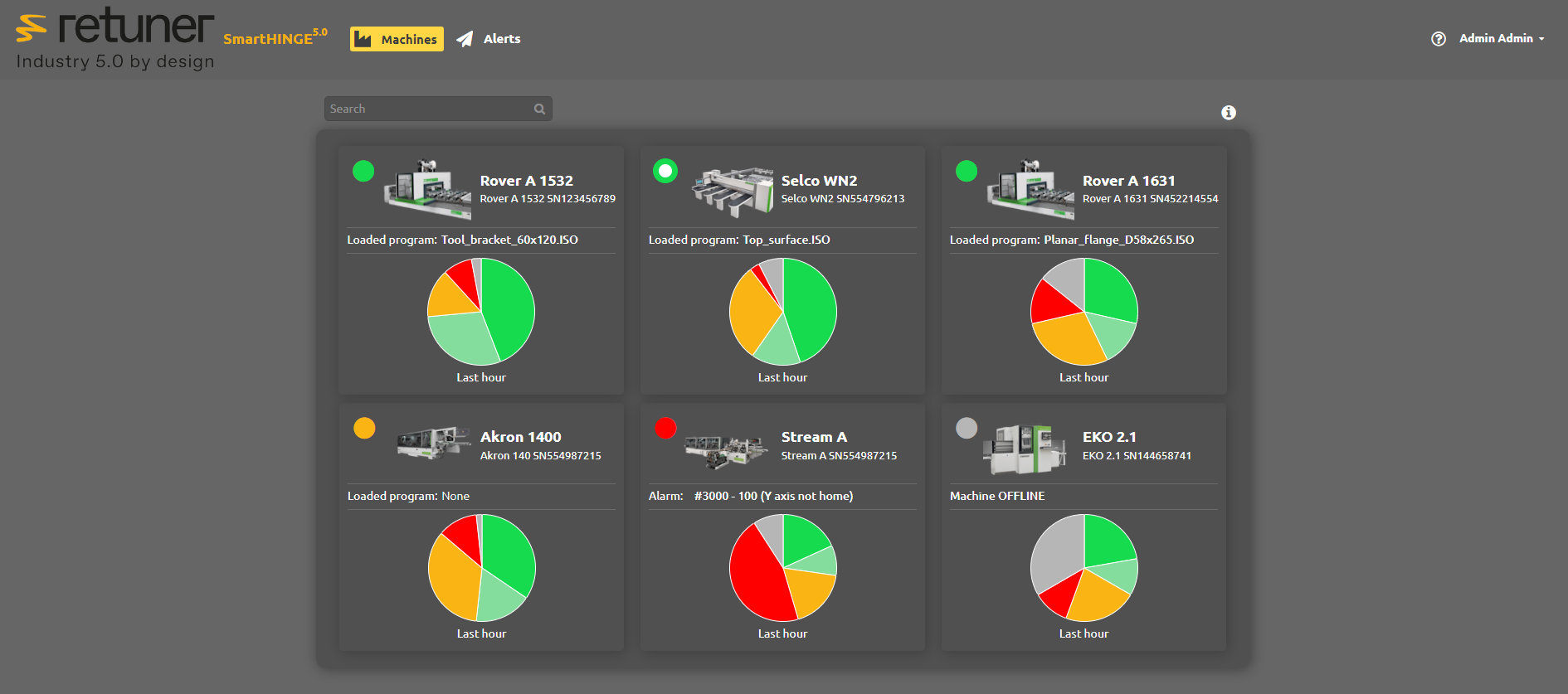

- A real-time system that recognises malfunctions and controls work conditions to avoid down time and production delays.

- A system to keep the factory efficient, safe, and sustainable.

- Offer new cloud-based systems to proactively support workers according to Industry 5.0

- Use the data acquired to implement continual improvements in production.

Our partners can adopt RETUNER technology to interconnect the shopfloor with company ICT systems. In addition, our partners can retail RETUNER software packages, supported by a wide range of services.

ASSISTANCE

- Remote assistance both pre and post sales, with DEMO and technical support

- Technical analysis of machine connectivity and successive appraisals

- Second level remote technical assistance in different languages

- Self-service ACTIVE TUTOR portal for the distribution and installation of software and user licences.

TRAINING

On-demand training and access to ACTIVE TUTOR portal for e-learning and FAQs

CO-MARKETING

- Joint participation in trade fairs, promoting products and connected services.

- Organisation of workshops, seminars, and conferences to take a deeper look at topics of common interest and improve partner training.

- Visibility on the company web site and social media channels, increasing the visibility and on-line reputation of partners.

- Joint communications through newsletters, dedicated brochures, and other marketing tools to increase brand knowledge and promote the products and services available.

- Personalised marketing material and support promoting RETUNER products.