An overview of Industry 5.0 for the chemical industry

May 31, 2024

The chemical industry is one of the key sectors of the global economy, fueling countless production processes and significantly contributing to technological innovation. It is also a sector characterized by high energy consumption and significant environmental impacts. With the advent of Industry 5.0, chemical companies have the opportunity to transform their operations, enhancing efficiency, sustainability, and social responsibility.

Energy consumption monitoring

One of the strategic elements of Industry 5.0 is advanced energy consumption monitoring. In the chemical industry, where production processes require large amounts of energy, implementing intelligent monitoring systems can lead to significant energy savings and CO2 emission reductions.

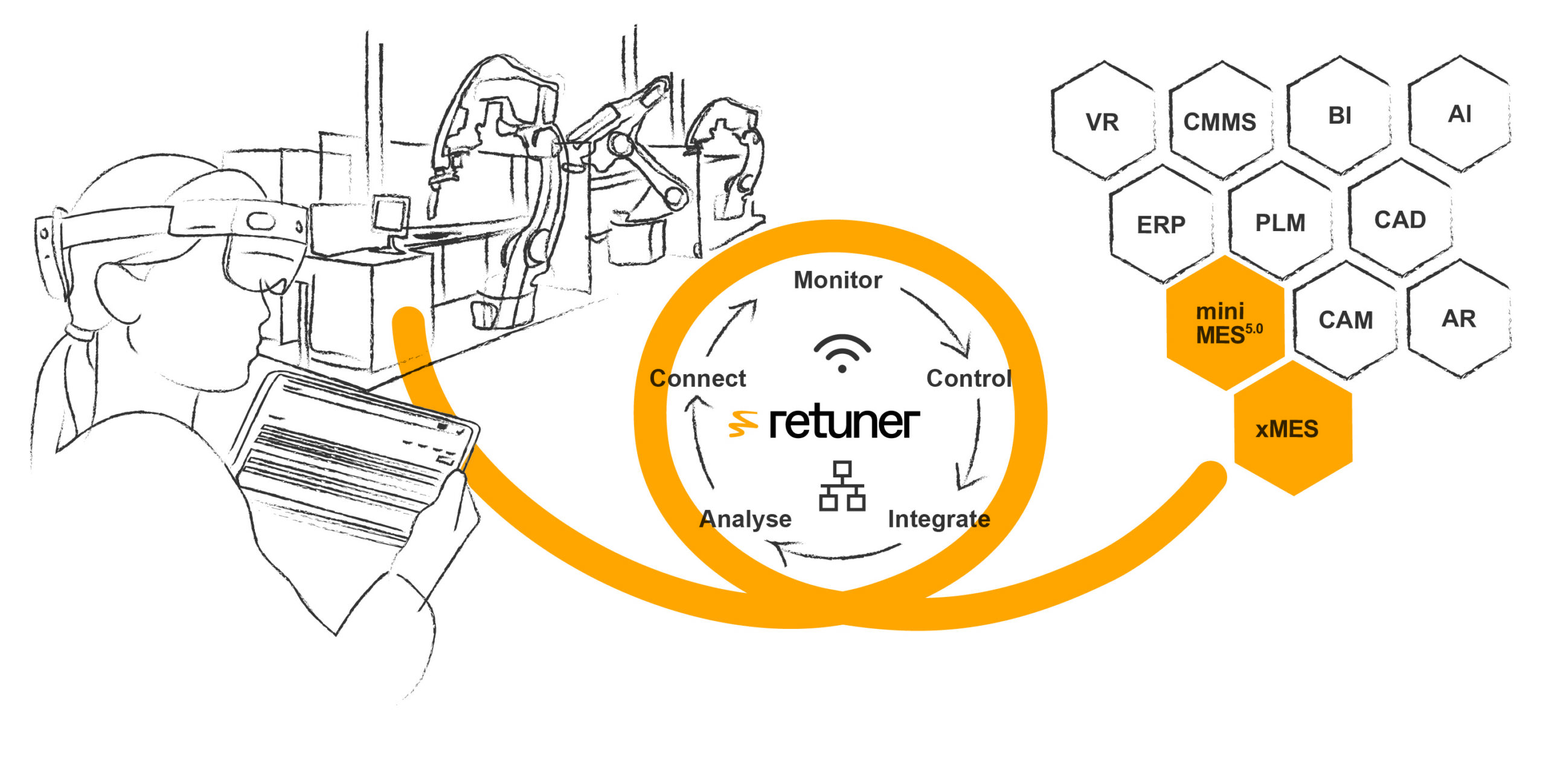

Thanks to the Industrial Internet of Things (IIoT) and advanced sensors, chemical companies can now monitor the energy consumption of each individual machine and process in real-time. These data are then analyzed using artificial intelligence (AI) algorithms to identify inefficiencies and suggest operational improvements.

Economic and environmental benefits

Optimizing energy consumption not only reduces operating costs but also contributes to environmental sustainability. Reducing the energy needed for production also means decreasing greenhouse gas emissions, thereby contributing to the sustainability goals of chemical companies. Moreover, companies that adopt advanced energy monitoring technologies can benefit from incentives and tax breaks provided for sustainable enterprises.

The Transition 5.0 Plan

The Transition 5.0 Plan is an initiative aimed at promoting the adoption of Industry 5.0 technologies across all industrial sectors, including the chemical industry. This plan aims to foster innovation, digitization, and sustainability by providing support to companies through funding, training, and consultancy.

The plan includes a series of measures to encourage companies to adopt advanced technologies. These include funding for the purchase of intelligent machinery, support for personnel training, and tax incentives for companies investing in digitization and sustainability projects.

One of the main goals of the Transition 5.0 Plan is to reduce the environmental impact of the industry by promoting the adoption of technologies that improve energy efficiency and reduce emissions. For the chemical industry, this means implementing cleaner and more sustainable production processes, using renewable resources, and reducing waste.

Monitoring corporate ESG

Using technologies such as machine learning and big data analytics, chemical companies can collect and analyze a wide range of ESG-related data. This includes greenhouse gas emissions, water resource usage, employee working conditions, and transparency in business practices. These data can be used to create detailed ESG reports and identify areas for improvement.

The growing focus on corporate social responsibility (ESG – Environmental, Social, and Governance) is pushing chemical companies to monitor and improve their environmental, social, and governance performance. Industry 5.0 offers advanced tools for monitoring and managing corporate ESG.

Intralogistics

Intralogistics is another crucial aspect that can benefit from Industry 5.0 technologies. In the chemical industry, optimizing intralogistics can improve operational efficiency and reduce costs.

AI-based intralogistics management systems can optimize workflows, minimize waiting times, and improve inventory management. For example, an intelligent system can predict material needs based on real-time production data and coordinate material movements to ensure that each stage of the production process has the necessary resources at the right time.

Optimizing intralogistics not only improves operational efficiency but can also lead to a reduction in waste and costs. Automated transport systems and intelligent inventory management can reduce the risk of human errors, improve product quality, and increase overall company productivity.

Conclusions

Industry 5.0 represents a revolution for the chemical industry, offering new opportunities to enhance efficiency, sustainability, and social responsibility. Through advanced energy consumption monitoring, corporate ESG monitoring, and intralogistics optimization, chemical companies can face future challenges with greater confidence and competitiveness. Investing in these technologies not only brings economic and environmental benefits but also helps build a more sustainable and responsible future for the entire sector.

Image via Unsplash