Details

Our web-based MES solution connects factory workers on any fixed or mobile device, for planning, monitoring, and keeping track of all stages of, or problems with production.

This permits the working out of costs of all stages of production, and the continual improvement of production thanks to the analysis of data in the section “Results”, integrated with business intelligence.

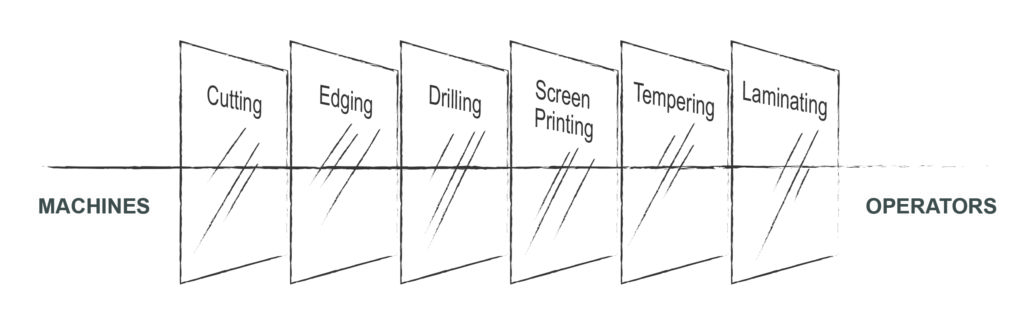

SMARTGlass5.0

RETUNER’s MiniMES5.0 is the ideal vertical solution for glass SMEs. It handles all phases of production from cutting to laminating.

The software was designed specifically for glasswork and guarantees high levels of efficiency and precision in every production phase.

Thanks to its flexibility and ease of use, RETUNER’s MiniMES5.0 is the perfect choice for this sector, even those companies that don’t yet use digital technology.

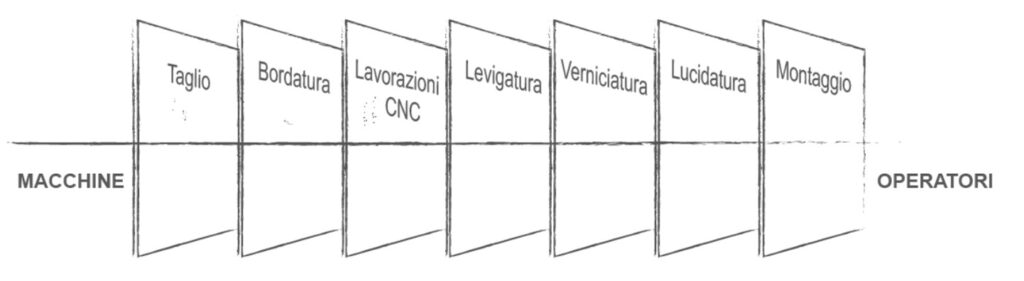

SMARTWOOD5.0

RETUNER’s MiniMES5.0 is the ideal vertical solution for woodworking SMEs.

Covering all phases of production from cutting to mounting, our software is designed to increase the efficiency of the production process. Thanks to the support of RETUNER’s MiniMES5.0, carpentry companies can optimise production and improve their management systems.

Download our practical guide to the Transition 5.0 Plan

Architecture

The RETUNER solution, placed between the factory and the organizational structure, connects and integrates the two levels according to a model of loose coupling. The main advantage is that the two levels can evolve independently over time, allowing for the change of machinery on one side or the replacement of application software on the other, without affecting their interconnection and integration.

Read more