MES software: how it works and features

April 19, 2024

MES software is the beating heart of production in the era of Industry 5.0. Let’s delve into how it works and its operational characteristics.

In recent years, the industrial world has undergone an epochal transformation, moving from traditional automation to the digital era. The advent of Industry 4.0 has revolutionized production processes, introducing concepts such as the Internet of Industrial Things (IIoT), artificial intelligence, and edge computing. In this scenario of continuous innovation, Manufacturing Execution System (MES) software plays a strategic role in ensuring the efficiency and competitiveness of manufacturing companies. In this article, we will delve into the meaning of MES, its impact on Industry 4.0, and how it is evolving in the era of Industry 5.0.

Table of Contents:

- What is MES?

- The role of MES software in industrial production

- MES in Industry 4.0

- Evolution in Industry 5.0

- Conclusions

What is MES?

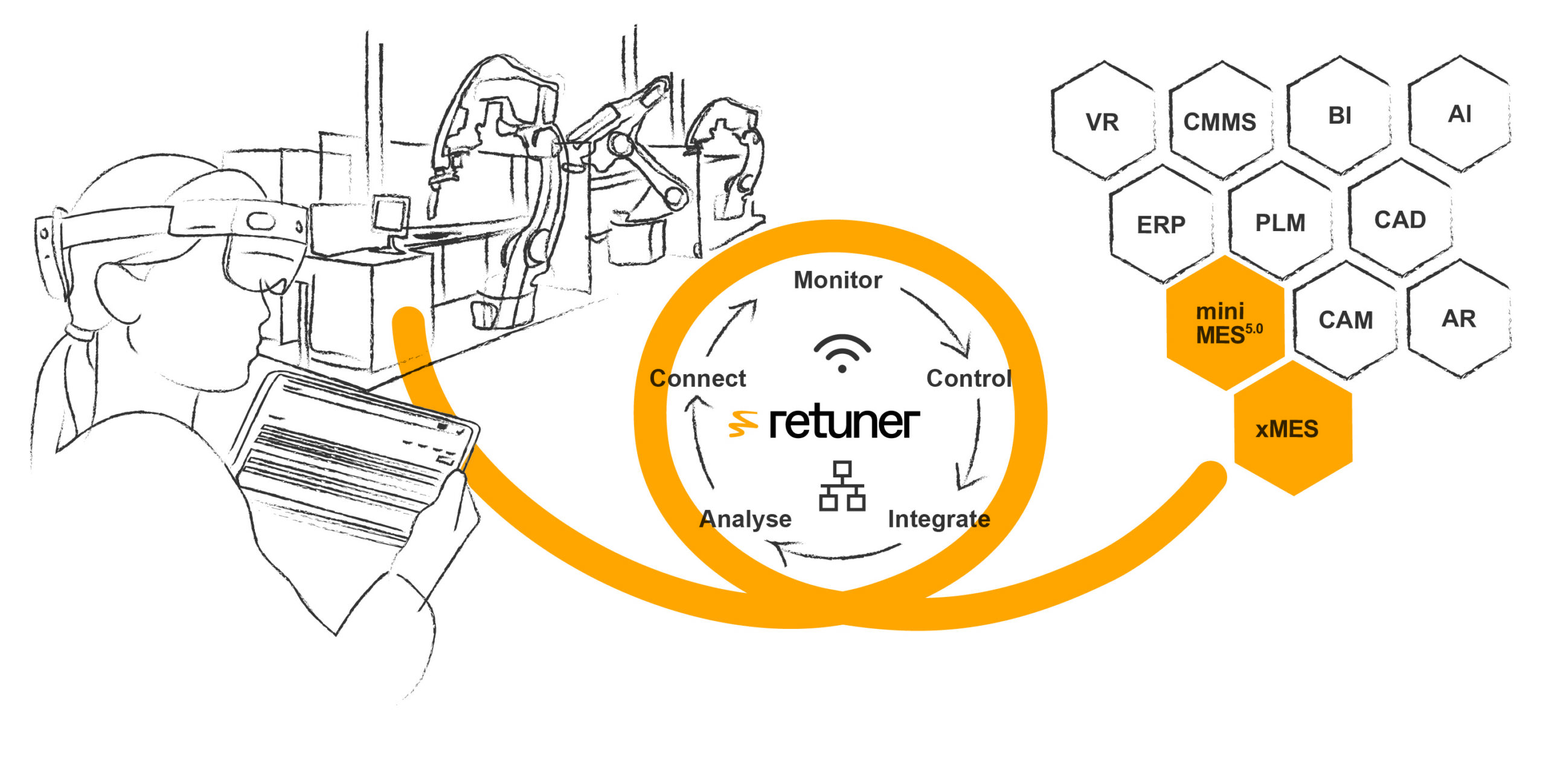

The term MES stands for Manufacturing Execution System. It is software designed to manage and monitor production processes in real-time. MES sits between the production planning system (ERP) and the operational level of the production process. MES translates the plans generated by the ERP into concrete production actions.

The role of MES software in industrial production

MES performs several crucial functions to optimize industrial production:

- Monitoring and control: MES collects data from the production process in real-time, allowing for performance monitoring and prompt intervention in case of anomalies

- Traceability: With MES, it’s possible to trace each individual product along the entire production chain, ensuring regulatory compliance and the quality of the final product

- Work order management: The software manages work orders, planning activities, and allocating resources efficiently to maximize productivity

- Quality management: Through integrated checks and inspections, it’s possible to ensure product quality and promptly identify any defects

- Cycle time optimization: By analyzing production data, MES identifies bottlenecks and proposes solutions to optimize cycle times and reduce waste

MES in Industry 4.0

In the context of Industry 4.0, MES assumes an even more crucial role. Integration with advanced technologies such as IIoT, AI, and real-time data analysis allows MES to provide unprecedented visibility and control over production processes. IIoT sensors, for example, can collect data on machine status and the work environment, while artificial intelligence algorithms can analyze this data to predict imminent failures and optimize performance.

Evolution in Industry 5.0

With the advent of Industry 5.0, which places even greater emphasis on human-machine interaction and mass customization, the role of MES is further evolving. Business MES systems are incorporating advanced collaboration and communication features, enabling greater interaction between human operators and automated systems. Furthermore, MES is becoming increasingly focused on managing complexity, supporting the production of smaller and customized batches without compromising efficiency and quality.

Conclusions

MES software plays a fundamental role in ensuring the efficiency and competitiveness of manufacturing companies in the digital era. Through advanced monitoring, control, and optimization functionalities of production processes, MES enables companies to adapt to the challenges and opportunities of Industry 4.0 and beyond. Investing in a robust and cutting-edge MES system is essential to remain competitive in an increasingly global and dynamic market.