Edge computing, what is it and what advantages does it offer

November 24, 2023

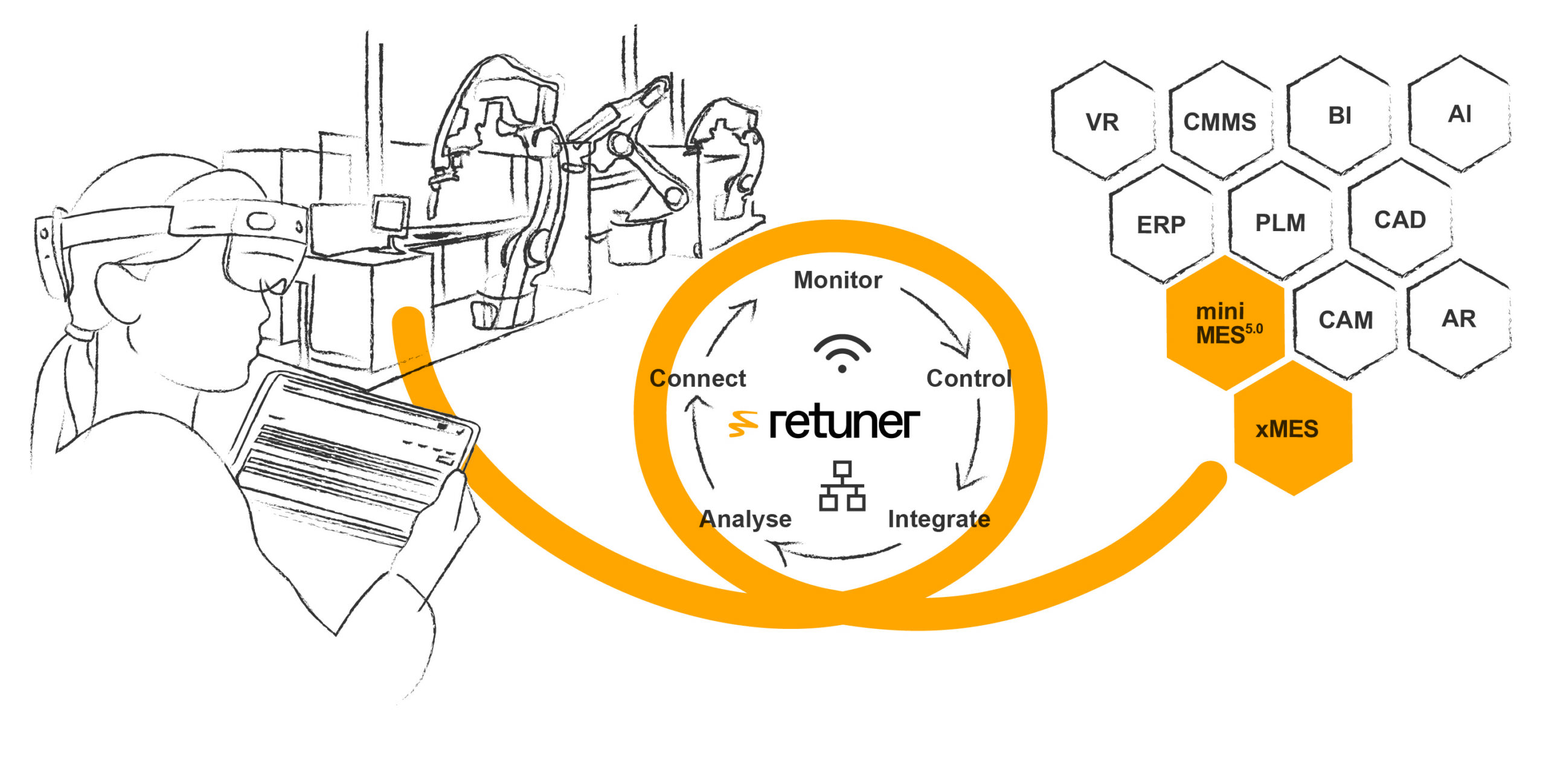

How can valuable information be obtained from connected machines to make strategic business decisions? Through the integration of edge computing platforms. Let’s see how.

Many things have changed in the digital factory compared to the past, with one major shift being the production of data. Sensors, monitoring systems, and IIoT (Industrial Internet of Things) devices have enabled the creation of large volumes of data, commonly known as big data.

Data are at the center of the digital revolution, but they must be managed and interpreted appropriately to generate strategic insights and improve efficiency and productivity. The network infrastructure plays an increasingly strategic role in the connected factory. In turn, the convergence of IT-OT has defined new systems for data collection, analysis, and transmission.

Cloud computing VS edge computing

For a long time, cloud computing has been the reference technology for the digitization of industrial processes. It is a reliable solution with a long history, and there are providers on the market today suitable for all needs.

Even today, cloud computing plays a fundamental role in the connected factory. Its strengths include distributed computational power and the possibility of ubiquitous real-time access. This translates into low access costs, high modularity, and integration with third-party applications.

However, it’s worth noting that cloud platforms require an efficient connection network for secure data transmission and protection against potential cyberattacks. While cloud computing is a consolidated technology, it proves to be less effective in certain production contexts.

The big data produced by sensors and connected machines are, by their nature, characterized by large volumes of small pieces of information. Individually, big data don’t reveal much. It is essential to process individual pieces of information to obtain the strategic insights that machines and sensors provide.

Transmitting big data for processing in cloud computing turns out to be inefficient, can be costly, and opens the door to security vulnerabilities. This is where edge computing comes into play.

Edge computing: features and advantages

In simple terms, edge computing is a distributed network infrastructure that processes data as close as possible to where the data is produced: on machine or within the factory. This has significant advantages. If we imagine the presence of hundreds of connected sensors within a production process, thanks to edge computing, data processing will be in real-time.

This improves latency, i.e., the data processing capability and its transformation into on-machine feedback. Greater speed means opening the doors to more efficient and effective decision-making processes. Edge computing also provides increased security.

Data remains within the factory perimeter, reducing the number of entry points from the outside. This also results in cost savings in terms of operational expenses. It’s important to remember that edge computing and cloud computing are two complementary worlds, where edge solutions handle the collection and analysis of raw data, which are then sent to external cloud platforms for transforming data into strategic information.

This enables the digital transformation and Industry 5.0, emphasizing maximum efficiency and productivity.

Image via Unsplash