Energy consumption monitoring in Industry 5.0

May 13, 2024

In a globally uncertain climate scenario, it is important for companies to be protagonists of virtuous change. This applies to both large multinational corporations and small and medium-sized enterprises.

In this perspective, energy consumption monitoring is becoming an increasingly strategic element. Optimizing and making consumption efficient means many things: naturally improving environmental impact. But also making companies more competitive and resilient in facing market challenges.

Industry 5.0 and energy consumption monitoring

Industry 5.0 represents a new phase of industrialization based on increasing collaboration between humans and machines. The merger of advanced digital technologies and traditional industrial processes paves the way for a new paradigm of intelligent and flexible production. This must be accompanied by increased attention to energy consumption monitoring.

Monitoring allows companies to identify areas of waste and implement strategies aimed at improving operational efficiency. Through real-time energy data analysis, companies can optimize processes, reduce costs, and increase productivity. For example, the implementation of automated control systems can adjust production according to energy demand, minimizing waste and ensuring optimal resource utilization.

In an era where environmental awareness is at the center of global debate, monitoring energy consumption is even more important. By reducing the environmental impact of industrial operations, companies can contribute to the fight against climate change and promote a sustainable future. Energy consumption monitoring allows companies to monitor greenhouse gas emissions and adopt corrective measures to reduce them.

Monitoring technologies and benefits

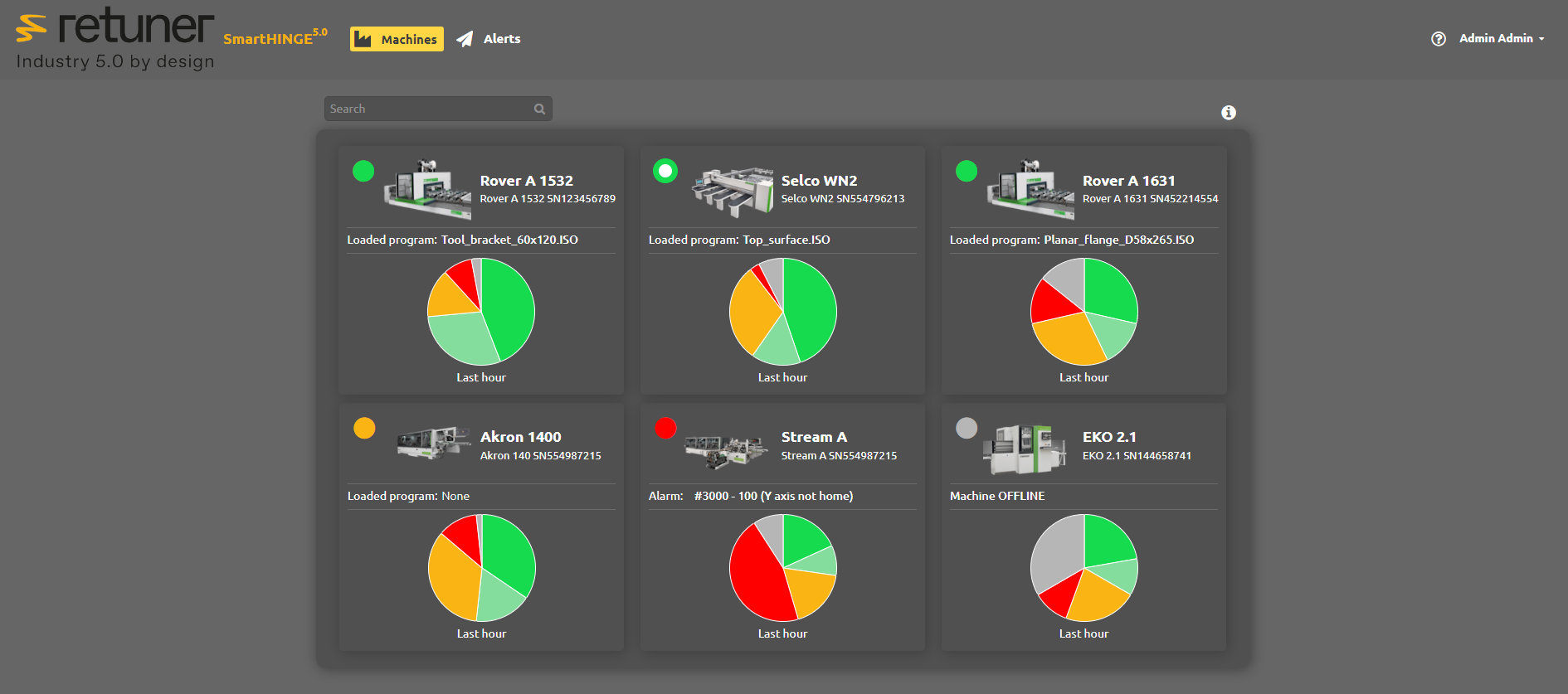

To successfully implement energy consumption monitoring in Industry 5.0, companies must rely on advanced technologies. IIoT sensors are essential for collecting real-time energy data from machinery and industrial devices. This data is then processed through data analysis systems, such as edge computing, to identify patterns and anomalies in energy consumption. Energy management platforms allow companies to visualize and monitor data intuitively, facilitating decision-making processes.

The adoption of energy consumption monitoring practices brings a series of tangible benefits to companies:

- Cost reduction: identifying and reducing energy waste leads to a decrease in operating costs

- Improvement of reputation: demonstrating a commitment to sustainability can improve the company’s image and reputation

- Regulatory compliance: energy consumption monitoring helps companies comply with environmental regulations and government policies

- Operational resilience: optimizing energy consumption makes industrial operations more resilient and competitive

Consumption monitoring and Transition Plan 5.0

In a perspective of Industry 5.0, energy consumption monitoring is now the central element of the innovation policies of the European Union and our country.

The new Transition Plan 5.0, approved by the Italian Council of Ministers on February 26, places a strong emphasis on the sustainability component of consumption. In this context, incentives for investments in software, systems, platforms, and applications for continuous monitoring or visualization of energy consumption are included.

The Transition Plan 5.0 is therefore a great opportunity for innovation and digital transformation. For all information about the plan, we refer you to the dedicated in-depth analysis.

MES for energy monitoring

xMES is our next-generation extended Manufacturing Execution System, which enables the integration of Industry 5.0 processes within production layouts.

Regarding energy consumption, xMES includes monitoring functionalities for all parameters related to the company’s ESG mapping.

Data is collected on field, certified, and normalized in real-time to be analyzed in depth. It is thus possible to define the energy consumption of each process and each individual piece produced.

The calculation between energy consumed and quantity of product obtained for each process allows for a clear definition of the energy consumption trend for each production.

Conclusions

Energy monitoring plays a fundamental role in Industry 5.0, allowing companies to improve operational efficiency and promote environmental sustainability. Through the adoption of advanced technologies and innovative practices, companies can maximize the benefits of intelligent energy management. In an increasingly interconnected and sustainability-oriented world, consumption monitoring is a fundamental step towards a more efficient and responsible industrial future.