VETRERIA PACHETTI: THE INDUSTRY 4.0 REVOLUTION IN A SMALL GLASS WORKING COMPANY

2023

THE CHALLENGE: Embracing Digital Transformation

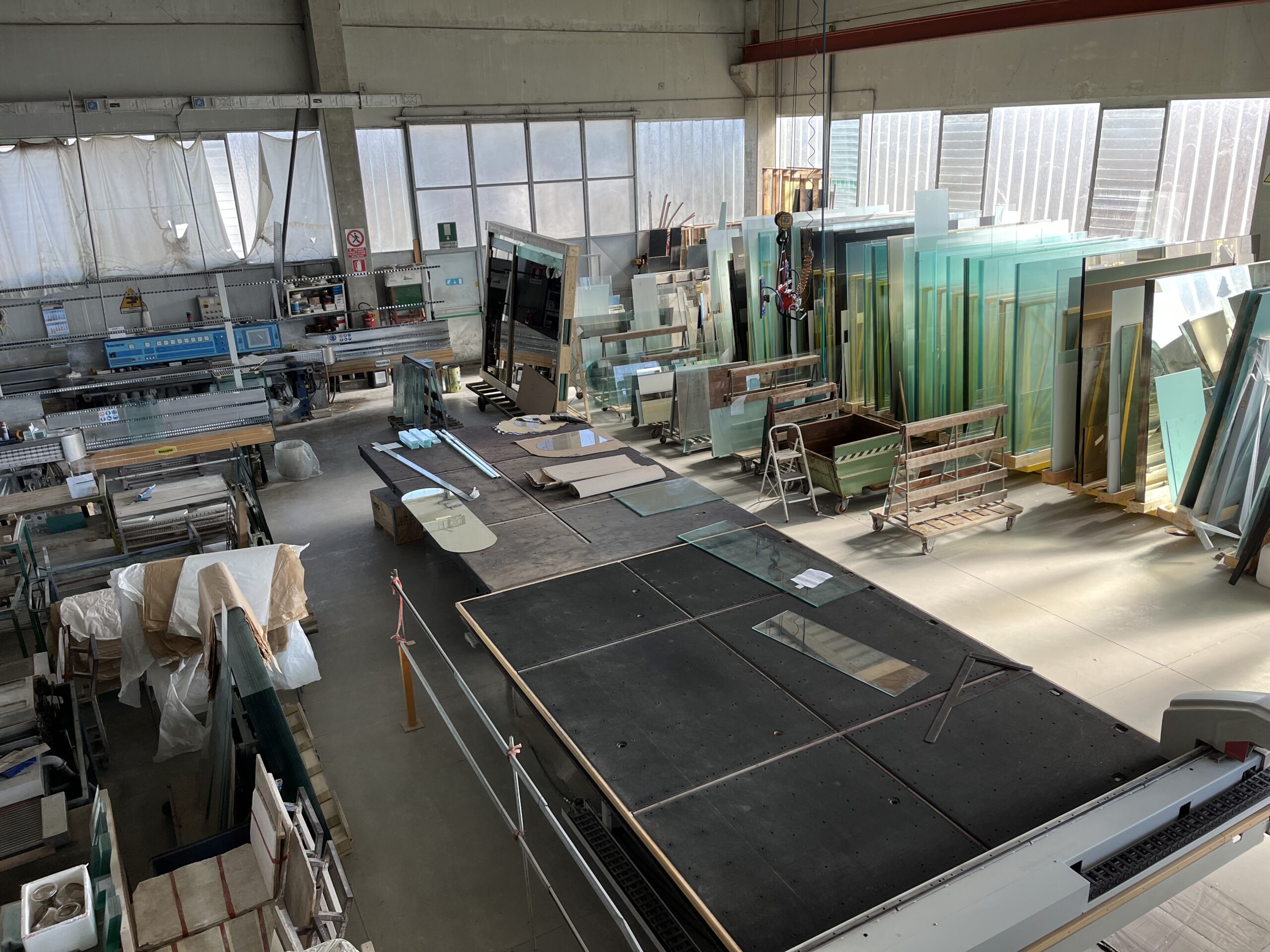

Vetreria Pachetti, a family-run business established in Tuscany, has been serving the local market for years. With a team of ten employees, six of whom are in production, the company specializes in flat glass processing. Their offerings include components for residential and commercial furniture, as well as mirrors and artistic stained glass.

In 2021, aiming to optimize its production process, the company decided to digitize its machinery. They interconnected the new MASTER BIESSE machine, leveraging the tax incentives provided by Italy’s Transition Plan 4.0. This marked the beginning of their complete shift to Industry 4.0 practices.

THE SOLUTION: SMARTCONNECTION by BIESSE

To manage their digital factory, Vetreria Pachetti adopted the MES component called SMARTCONNECTIO by BIESSE, powered by RETUNER®. This production management system is specifically designed for small and medium-sized manufacturing companies in the glass industry. Its primary function is to connect production operators on any device, enabling them to track all production stages. The system allows operators to record activities, stoppages, production progress, and anomalies.

THE BENEFITS: Improved Efficiency and Resource Management

The introduction of SMARTCONNECTION brought several advantages to the company:

- Enhanced Planning: The digitization and traceability of job orders improved planning capabilities.

- Improved Monitoring: Real-time tracking of job order progress within the production process became possible.

- Optimized Delivery Management: The visualization of the processing schedule helped manage delivery times more effectively, accounting for machine operational overloads.

- Efficient Resource Utilization: Better use of company resources was achieved.

This software revolutionized the company’s production process. So much so that Vetreria Pachetti decided to extend its application to all production processes. They also subscribed to the maintenance plan for new software versions to maintain Industry 4.0 compliance.

CUSTOMER TESTIMONIAL: A Success Story

“SMARTCONNECTION has allowed us to digitize the job order and know its progress at any time within the production process. Additionally, the visualization of the processing schedule has enabled us to better manage delivery schedules, always considering the operational overload affecting the machine,” says Massimo Pachetti, owner of the company.