OMV VISMARA CHOOSES ORCHESTRA FOR DIGITAL TRANSFORMATION

2024

Seeing is Believing

It is always more reassuring to see a product with your own eyes. For this reason, OMV Vismara invites customers to explore and test its technologies in a dedicated showroom. This hands-on experience builds trust and helps customers understand the true value of the solutions offered.

Industry 5.0: Sustainability in Manufacturing

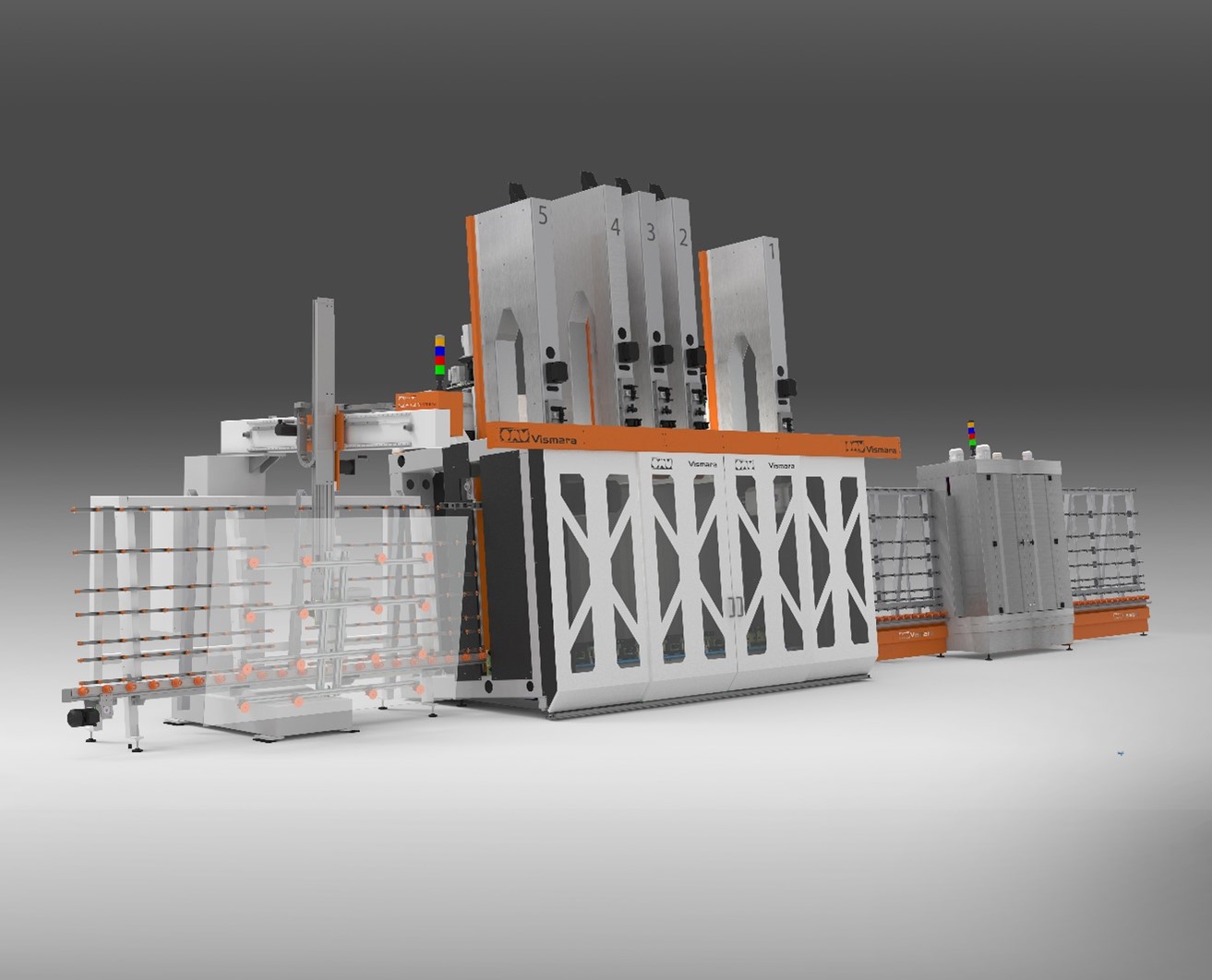

OMV Vismara offers a comprehensive range of machines for processing flat glass. These include vertical drilling and boring-milling machines, as well as horizontal drilling systems. Additionally, the company produces washing machines, Cartesian loaders and unloaders, grinding machines, and filleting machines.

Thanks to this variety, customers can rely on a single point of contact for their complete processing line. The true strength of OMV lies in its attention to detail. This focus is present throughout the machine’s lifecycle—from design to after-sales support.

Embracing Digitization: From Industry 4.0 to 5.0

In today’s digital era, machines must align with Industry 4.0 and 5.0 standards. OMV Vismara has responded by integrating digital capabilities into its products, offering turnkey solutions ready for immediate implementation.

In 2022, OMV partnered with Orchestra, a strategic technology provider. This collaboration helps manufacturing customers take advantage of government incentives under the Transition 4.0 and 5.0 Plans.

RETUNERGY 5.0: More Than Just Monitoring

Through this partnership, OMV customers gain access to RETUNERGY 5.0, a complete solution offered by Orchestra. It includes advanced tools to monitor energy consumption during production. Moreover, it supports paperwork and appraisal management, streamlining administrative processes.

Why Choose RETUNER®?

The RETUNER® suite delivers a wide range of benefits, grouped into four main areas:

- Connectivity: OMV machines can easily connect to enterprise ICT systems, other machines, and production lines.

- Real-time Control: Customers receive certified, normalized data. This allows them to monitor and manage production in real time.

- Business Intelligence: Built-in BI tools within the MES system provide insights into performance. As a result, business owners can improve competitiveness and operational resilience.

- Sustainability Tracking: The new xMES features measure sustainability targets, particularly energy consumption. Furthermore, they integrate seamlessly with the supply chain.

What Customers Say

“A simple program for a single machine, which—on request—can expand to include multiple machines, even from different manufacturers. It also interfaces with existing management systems already in use within the customer’s company.”

— Mauro Vismara, Owner of OMV Vismara